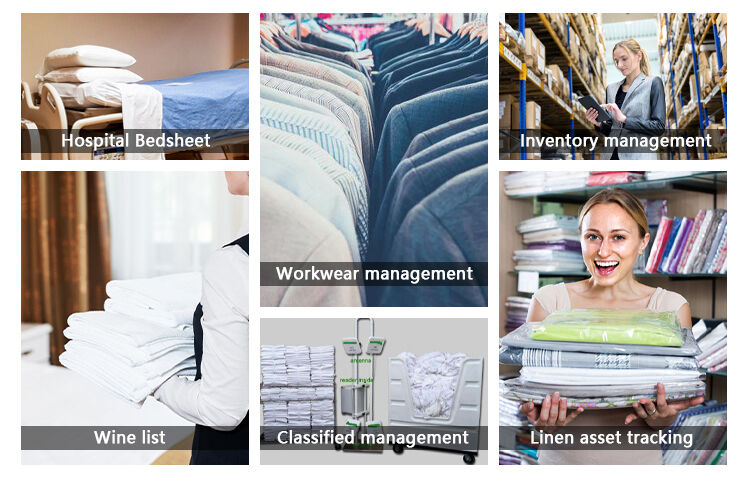

UHF laundry tags can also be called UHF linen tags. Their applications are not limited to laundry, but can be extended to other areas. For example, they can be used in Automate the process of laundry,Hospital uniform and hotel bed sheet washing and tracking;Enterprises uniform attendance management,asset management, logistics management, and healthcare to track and manage items.

RFID laundry tags use radio signals to identify and transmit information. Their operation mainly involves three steps: data writing, information reading, and back-end management.

Data Writing: During textile production or initial use, RFID tags are embedded or sewn onto the items.

Information Reading: During washing or distribution, when a textile with an RFID tag enters the reader's radio frequency range, the reader sends an excitation signal to the tag. Upon receiving the signal, the tag draws energy and activates its chip, which then transmits the stored information back to the reader via an antenna.

Back-end Management: The data read by the reader is transmitted to a back-end management system, where it is stored and analyzed. Managers can view the status and location of each item in real time through a software interface.

Product Name |

Textile UHF RFID Laundry Tag |

Material |

50/50 polycotton |

Size |

35mm x 15mm; 58mm x 15mm; 70mm x 10mm 70 x 15 mm 75 x 12mm 75 x 15 mm or customized |

Weight |

0.3g |

Oprating frequency |

865~868MHz,902~928MHz |

Memory |

96 bits EPC |

Chip |

U8, U9, M730, MR6, M750 etc for option |

Reading distance |

Up to 5m(Fixed reader) |

Mounting method |

Sewing, Heat-sealing, Pouch |

Affixes to |

Linens and garments |

Warranty |

First of 200 wash cycles or 100 autoclave cycles or 3 years from ship date |

Typical washing cycle |

Washing: +90°C (I94°F), I5 minutes |

|

Drying: +I80°C (356°F), 3 minutes |

|

lroner: +200°C (392°F), I2 seconds |

|

Water Extractor: 60 bar, 80 seconds |

Autoclave |

Air removal: +I00°C (+2I2°F), 5 minutes, 0.I bar |

|

Sterilizing: +I34°C (+273°F), I0 minutes, 3.25 bar |

|

Sterilizing: +I34°C (+273°F), I0 minutes, 3.25 bar |

Patching instructions |

+204°C' (399°F), 12 seconds, 0.5 kg/cm2 |

Storage Temperature |

-40°C' to +I20°C (-40°F to +248°F) |

Certifications |

OEKO-TEX® Standard 100 product class II, MR Conditional (I.5T - 3T) |

Copyright © ©Copyright 2024 Greatest IoT Technology Co., Ltd all rights reserved - Privacy policy